-40%

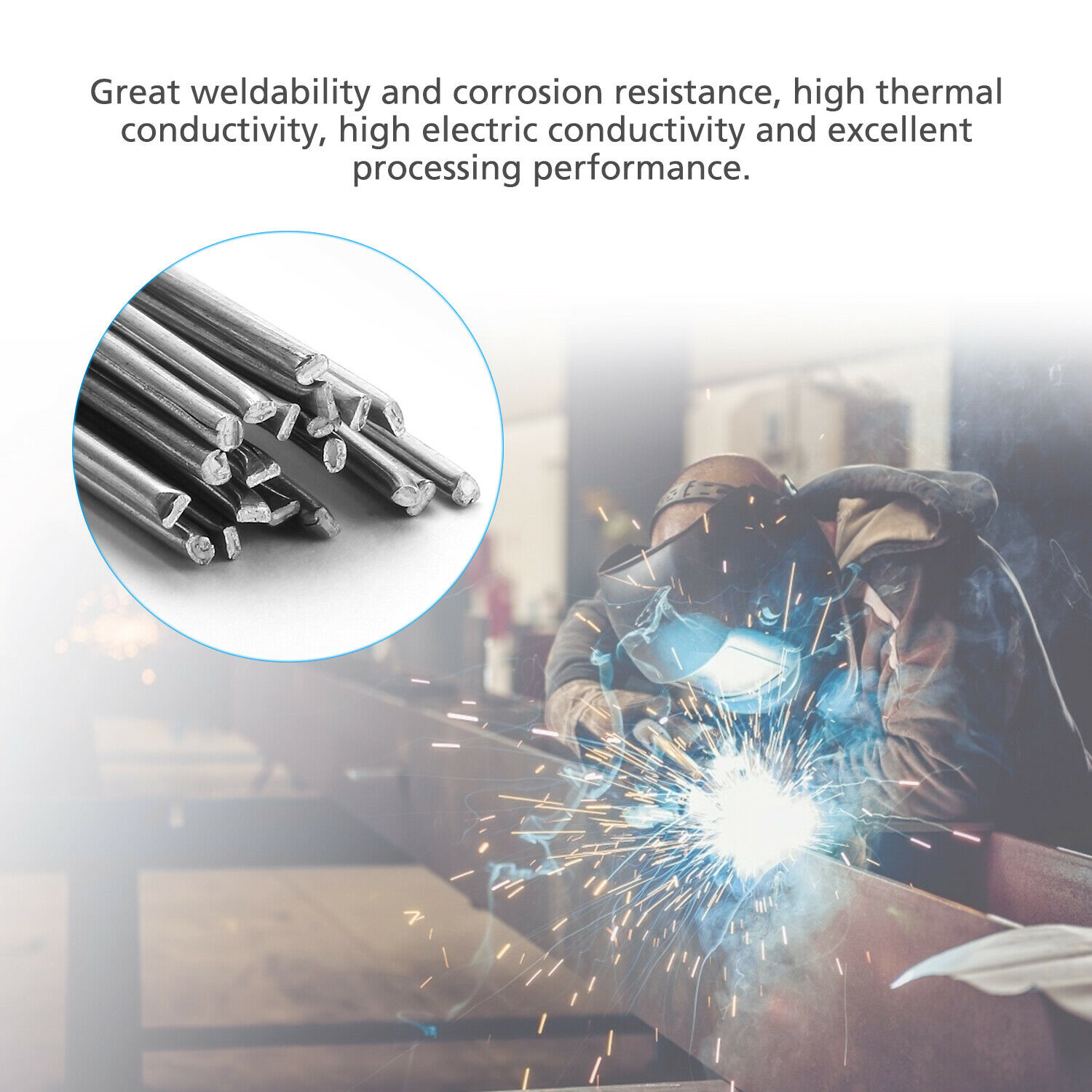

20X Aluminum Solution Welding Flux-Cored Rods Wire Brazing Rod 1.6MM x 50CM MAGI

$ 4.21

- Description

- Size Guide

Description

Product Features:The easy to melt welding rods are high-quality special rods that are mainly used for welding / brazing aluminum and aluminum alloys. However, they can also be used for hard welding non-ferrous metals other than stainless steel.

Recommended for welding aluminum alloys: 1060, 1350, 3003, 3004, 3005, 5005, 5050, 6053, 6061, 6951, 7005 and cast alloys 710.0 and 711.0

Applications include cargo areas, loading ramps, docks, diamond plates, irrigation lines, engine blocks, gearboxes, etc.

Prepared for small repairs. For repairs that would compromise safety if they are not repaired, we recommend replacing the parts completely instead of repairing them.

Product Specification:

Quantity: 20PCS

Material: Aluminum

Color: Silver

Melting Point: 647°~658°

Diameter: 2mm / 0.08"

Length: 500mm / 19.7"

Recommended for welding or brazing aluminum alloy: 1060, 1350, 3003, 3004, 3005, 5005, 5050, 6053, 6061, 6951, 7005, and cast alloys 710.0 and 711.0

Item Wight: Approx. 3.5g / 0.12in (One Aluminum Welding Wire)

Package Size:

51 * 1 * 1cm / 20.1 * 0.4 * 0.4in(20PCS)

Approx. 75g / 2.6in (20PCS)

Package Include:

20 * Aluminum Welding Wire(20PCS)

How to use:

Step 1: Clean and polishe the physical surface.

Step 2: Heat the surface of the base material, until the temperature of the wire to the operating temperature of 380°~400°, so you can rely on the parent metal heat transfer welding wire to form welds, should not use the flame to burn wire, When the surface temperature of the base metal is sufficient, the wire can flow well and penetrate into the metal capillary.

Step 3: When repairing thin aluminum, as long as the aluminum base metal heated to the appropriate working temperature, and then use the wire back and forth friction melting to form a weld, only with a metal brush melt welding wire to weld at the weld.

Step 4: Use propane gas to weld s mall object, use industrial gas or induction heating device to heat and weld big object, natural slow cooling after welding.

* Any problems pls contact us at any time before leaving a negative/neutral feedback. Many thanks to you.