-40%

ERCuSi-A Silicon Bronze TIG Welding Rod - 36" x 1/8"- (2 Lb)

$ 12.03

- Description

- Size Guide

Description

Powered byFrooition

All Items

See our eBay store for more great items >>

Shop Categories

Other

WELDING & CUTTING EQUIPMENT

OXY-FUEL EQUIPMENT

OTHER GAS REGULATORS

FILLER METALS

ABRASIVES

MAPP & PROPANE BRAZING TORCHES

WELDING CABLE

PVC VALVES

REFRIGERANT GASES

CARGO MANAGEMENT

GLOVES AND PROTECTIVE APPAREL

MAGNETIC HOLDERS

ELECTRODES OVENS/DRYERS

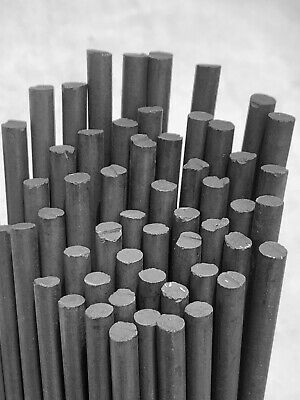

ERCuSi-A Silicon Bronze TIG Welding Rod - 36" x 1/8"

Item Description

ERCuSi-A Silicon Bronze Welding Rod

Silicon Bronze is a copper alloy Rod containing 3% silicon and used for TIG or Oxyacetylene Welding of copper, brass, bronze, steel and cast iron.

Silicon Bronze is best known for welding plain or galvanized steel sheet metal in the manufacturing of steel cabinets, metal furniture

and

ductwork.

Weld deposits demonstrate high strength, excellent corrosion resistance,

and

good weldability, making this wire suitable for surfacing parts in corrosive environments - Tensile Strength: 51,000 psi

Diameter: 1/8" (3.2mm) - Length: 36"

You will receive 2 Lb of Rods

Other Sizes and Packages:

ERCuSi-A - 36" x 0.035"- (1 Lb)

ERCuSi-A - 36" x 0.035"- (2 Lb)

ERCuSi-A - 36" x 0.035"- (5 Lb)

ERCuSi-A - 36" x 0.035"- (10 Lb)

ERCuSi-A - 36" x 0.045"- (1 Lb)

ERCuSi-A - 36" x 0.045"- (2 Lb)

ERCuSi-A - 36" x 0.045"- (5 Lb)

ERCuSi-A - 36" x 0.045"- (10 Lb)

ERCuSi-A - 36" x 1/16"- (1 Lb)

ERCuSi-A - 36" x 1/16"- (2 Lb)

ERCuSi-A - 36" x 1/16"- (5 Lb)

ERCuSi-A - 36" x 1/16"- (10 Lb)

ERCuSi-A - 36" x 3/32"- (1 Lb)

ERCuSi-A - 36" x 3/32"- (2 Lb)

ERCuSi-A - 36" x 3/32"- (5 Lb)

ERCuSi-A - 36" x 3/32"- (10 Lb)

ERCuSi-A - 36" x 1/8"- (1 Lb)

ERCuSi-A - 36" x 1/8"- (2 Lb)

ERCuSi-A - 36" x 1/8"- (5 Lb)

ERCuSi-A - 36" x 1/8"- (10 Lb)

Data Sheet:

ANSI/AWS A5.7 Class ERCuSi-A

ASME SFA-5.7 Class ERCuSi-A

Description and Application

Silicon Bronze is a copper alloy wire containing 3% silicon and used for GMAW, GTAW or Oxyacetylene Welding of copper, brass, bronze, steel and cast iron.

Silicon Bronze is best known for welding plain or galvanized steel sheet metal in the manufacturing of steel cabinets, metal furniture,

and

ductwork.

Weld deposits demonstrate high strength, excellent corrosion resistance,

and

good weldability, making this wire suitable for surfacing parts in corrosive environments.

Chemical Composition of ERCuSi-A:

Cu

Zn

Fe

Si

Al

Pb

Mn

Sn

Others

Balance

1.0

0.5

3.03

0.0025

0.0044

1.5

1.0

0.214

Single values are maximum unless otherwise specified.

Approximate Melting Temperature: 1866°F (1019°C)

Average As-Welded Brinell Hardness: 80 – 100 Brinell

Tensile Strength: 51,000 psi

Density: 0.308 lbs/in

3

Welding Parameters:

MIG Welding:

Recommended GMAW (MIG) Welding Parameters – DCEP (DC+)

3,4,6

*Spray Transfer: 100% Argon on Thin Sections; 75% Argon 25% Helium on Thicker Sections

Wire Diameter

Amperage

Volts

Wire Feed (ipm)

Flow Rate (CFH)

0.023” (0.6mm)

60 – 120

21 – 22

460 – 580

20 – 25

0.030” (0.8mm)

130 – 160

21 – 24

450 – 525

20 – 30

0.035” (0.9mm)

165 – 190

24 – 25

420 – 460

25 – 30

0.045” (1.143mm)

205 – 235

26 – 28

295 – 325

30 – 35

1/16” (1.6mm)

270 – 310

27 - 31

190 – 275

35 – 40

TIG Welding:

Recommended GTAW Welding Parameters

5,6

*100% Argon – DCEN/DC- or ACHF –2% Thoriated, 2% Ceriated, 2% Lanthanum or Rare Earth Tungsten

Wire Diameter

Tungsten Size

Amperage

Voltage

Flow Rate (CFH)

1/16” (1.6mm)

1/16”

80-170

12

20

3/32” (2.4mm)

3/32”

140-275

20

1/8” (3.2mm)

1/8”

200-375

25

5/32” (4.0mm)

5/32”

260-475

30

Oxyacetylene Welding:

The oxyacetylene gas flame should be slightly oxidizing (neutral) to keep the weld puddle small in order to allow fast solidification and this will also minimize cracking; use a borax type flux both before and during welding; preheating is not recommended.

5

When TIG welding with Silicon Bronze, best results are obtained by keeping the weld pool small; Preheating is not required; welding can be done in all positions, but the

flat position is preferred

6

Recommended parameters will be affected by changes in position, base metal, equipment and shielding gas.

About Us

About Us

Payment

Shipping

Returns

Disclaimer

About Us

Mundaka Technologies, Inc is a US-based company with an inherited expertise of more than 35 years in the welding, cutting and industrial gases business. We serve the United States and the Latin American markets from our facilities in Fort Lauderdale FL. All of our products are selected with quality and affordability in mind. Our customer service team is always available and committed to answering our client's questions and needs. NO Answering Machines, NO Excuses.

Payment

Payment

We accept all major payment methods: PayPal, Visa, MasterCard, AMEX, Discover, and Bank Transfers. We charge 6% sales tax on all orders shipping within the State of Florida. We sell with tax exemption if we are provided by the customer with a valid Florida resale certificate.

Shipping

Shipping

We ship the same business day for orders placed before 15:00 EST. USPS Priority Mail (1-3 days) and FedEx Ground (1-5 days), are our preferred shipping methods and delivery dates may vary according to tho the final destination of the order. For smaller and lighter items we use USPS First Class (1-4 days). We offer free shipping to the 48 contiguous continental states.

Returns

Returns

If you are not happy with your product, just request a return on eBay or get in contact with us, We will accept your return and refund your payment, no questions asked!. If you changed your mind or bought a product by mistake, Just send it back! we will refund your payment. Is the product that you bought does not fit your current equipment, No problem, just call us and we will help you to find the right equipment for you and exchange it. We are committed to providing our customers with a solution.

Disclaimer

Disclaimer

Mundaka Technologies Inc offers products that can operate at high temperature, high pressure, and high voltage/amperage. These products are intended for professional or trained users. Mundaka Technologies does NOT sell any products intended to diagnose, treat, cure, or prevent any disease and the products bought from Mundaka Technologies Inc should never be used as a reference to measure or dosage medical oxygen or any other medical gases or substances to humans or animals. Mundaka Technologies, Inc. assumes no liability for misuses of this products. Some of the products offered here might be described as "Compatible with" other manufacturer´s equipment and brands. It is not in the Mundaka Technologies Inc intentions to resemble, copy, counterfeit or violate trademarks, patents, brands or any other form of intellectual property owned by other companies not affiliated, associated, authorized, endorsed by, or in any way officially connected to Mundaka Technologies Inc.

Helpful Links

Add to Favorite Sellers

Sign up to Newsletter

View Feedback

Contact Seller

Visit seller's eBay Shop

About Seller Page

More Items!

View more great items

Powered by

Frooition

Frooition | No-js Template | eBay design, eBay store design, eBay shop design, eBay template design, eBay listing design (ver:froo_no_js)

This listing is currently undergoing maintenance, we apologise for any inconvenience caused.