-40%

ZENA 1/8" NO-Gas Arc Brazing Rods -- Braze WITHOUT Gas!

$ 10.53

- Description

- Size Guide

Description

ZENA®

NO-Gas

tm

Arc Brazing Rods

Use your Arc Welder for Brazing!

SquareTrade © AP6.0

Now you can braze anywhere you that you can arc weld without the need for an oxyacetylene torch, hoses, regulators, or expensive and heavy gas bottles!

These incredibly versatile ZENA® NO-Gas Arc Brazing Rods let you braze and fill with a high quality high tensile strength (50,000 lb. / 18% elongation) bronze alloy using only your arc welder!

You can also use these special arc brazing rods for:

joining copper alloys to stainless steel and ferrous metals, including cast iron, OR

for increasing salt water corrosion resistance,

OR

to produce large, heavy bronze overlays.

Description:

Highly versatile, smooth running, easy-to-handle, Bronze alloy electrode rod for both ferrous and nonferrous applications.

Use for filling in defects on brass and bronze, joining copper alloys to ferrous metals, including cast irons, for salt water corrosion resistance and where large, heavy overlays are required.

Mechanical Properties:

Tensile Strength

(psi & N/mm

2

)

Yield Strength

(psi & N/mm

2

)

Elongation

Hardness

50,000 psi

(340 N/mm

2

)

30,000 psi (210 N/mm

2

)

18%

Brinell 105, Rockwell B78

Recommended Welding Current Type / Polarity:

AC or DC straight polarity (electrode negative)

Recommended Amperage:

100 - 135 Amps

Rod Diameter:

1/8"

Product Features:

Excellent wear resistance.

Ideally suited for heavy overlaying and joining galvanized steels, copper, bronze, brass or any combination.

Typical Applications:

Cams

Pumps

Valves

Pulleys

Pistons

Housings

Impellers

Bushings

Axle Stops

Tail Pipes

Key Ways

Floor Plates

Coils

Chrome-Moly

Gears

Guards

Piping

Cams

Cast Legs

Manifolds

Propellers

Mixer Arms

Feed Screws

Shaft and Sheaves

Bearing Surfaces

Conveyor Guides

Crosshead Slides

Drive Sprockets

Drill Bit Extensions

Mufflers

Recommended Welding Techniques:

Clean weld area.

Preheat is not necessary except for heavy or complex sections which should be preheated to 400 F (200 C).

A close arc should be maintained.

Fill in craters prior to extinguishing arc.

Use a slight weaving technique or a stringer bead.

Upon cooling, slag can easily be removed by light chipping and brushing.

For multi-pass work, it might be necessary to reduce amperage setting as base metal increases in temperature.

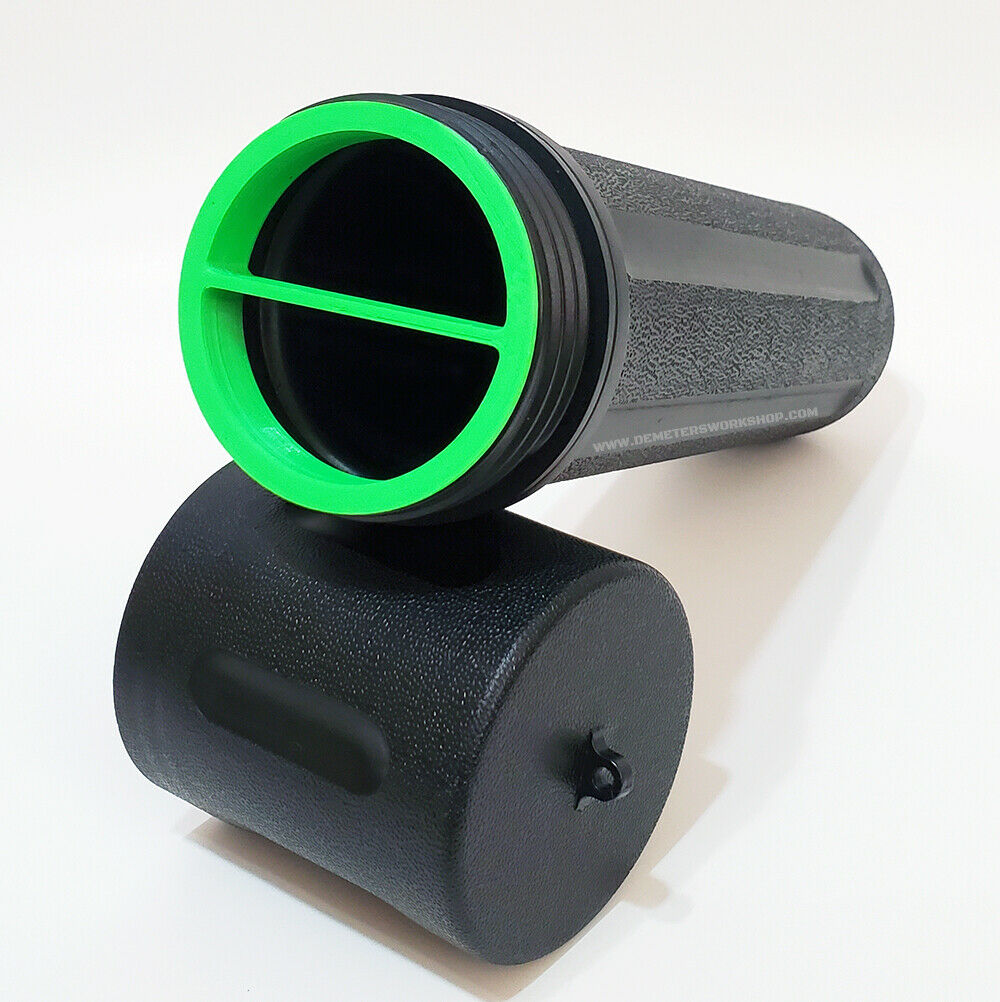

Packaging:

1 lb. box (14 rods)

Larger packs/quantities available as special order items.

ZENA

and NO-Gas are trademarks owned by ZENA, Inc. for its welding systems and related products.

©

Copyright 2004 by ZENA, Incorporated. All rights reserved.

NOTE: These rods will work with engine driven welders made by Miller, Lincoln, Hobart, Century, Esab, HTP, Mitsubishi, Thermal Arc, and other companies. When comparing rod specifications, you will find that they function well with ZENA 150A and 200A welders which are comparable to, and will do the same job as, for example, a Miller 225 Bobcat welder, a Hobart 250A welder, a Century 200A welder, or a Lincoln Ranger 8 welder. Of course, 160A, 175A, 180A, 275A, or even 300A, or 400A welders would be also in the same category. MIG and TIG torches made by companies like Tweco and Forney are also compatible with this technology.

NOTE2: In addition to service trucks (particularly popular are Ford Chevrolet and Dodge Diesels) and all types of 4x4's (including Jeep, International, and Toyota), these rods can also be used with all types of heavy equipment, including backhoes, front end loaders, track loaders, forklifts, and tractors as well as all types of utility vehicle.